Regulation 19 Rutland Local Plan

Chapter 10 – Minerals and Waste View responses

Minerals

As the Minerals Planning Authority (MPA), Rutland is responsible for setting out the spatial strategy for mineral extraction in the County, defining Mineral Safeguarding Areas, identifying the provision of minerals to be met in Rutland over the plan period; planning for this provision by identifying sufficient opportunities for extraction; and setting out development criteria against which planning applications will be assessed.

Spatial Strategy for Minerals Development

What will the policy do?

The Mineral Spatial Strategy will set out where new minerals development should be located, including both mineral extraction and facilities for the processing of recycled aggregates. This is necessary to guide future mineral development and investment.

Policy MIN1 - Spatial strategy for minerals development View responses

Extraction of mineral resources, in particular limestone for aggregate purposes and limestone and clay for cement purposes, will be focussed within the:

- Limestone for aggregates and building stone Area of Search (AoS), and

- Cement primary and secondary materials AoS.

Small-scale extraction of non-aggregate minerals for building/roofing stone and clay, where linked to historic environment conservation outcomes, will be supported in rural areas or within settlements.

Recycled aggregate facilities should be in general conformity with the spatial strategy and development principles for waste management and disposal (Policy WST1).

Why is this policy needed?

National policy recognises that minerals are essential to support sustainable economic growth and our quality of life. However, as minerals are finite natural resources and can only be worked where they are found, it is important to make best use of them to secure their long-term conservation.

The NPPF states that Minerals Planning Authorities (MPAs) should plan for a steady and adequate supply of minerals of economic importance by identifying in their Local Plans, sites and/or areas for minerals extraction in appropriate locations. The Government also encourages MPAs to take account of the contribution that secondary and recycled materials can make to the supply of materials in preference to the extraction of primary materials as part of a circular economy.

It is important to note that minerals can only be worked where they are found, however where possible the Plan seeks to relate minerals development with growth or market areas and to reflect local circumstance such as features of significance, in particular Rutland Water and Ketton Cement Works. Within Rutland, minerals considered to be of economic importance for aggregate purposes include limestone and for non-aggregate purposes include limestone and clay. Recycled aggregates (inert CD&E – Construction, Demolition and Excavation - waste) are also produced within Rutland.

Geology of Rutland

The particular geology of the area has given its name to the Rutland Formation which was formed from muds and sand carried down by rivers and occurring as bands of different colours, each with many fossil shells at the bottom. At the bottom of the Rutland Formation is a bed of dirty white sandy silt. Under the Rutland Formation is a formation called the Lincolnshire Limestone. The best exposure of this limestone (and also the Rutland Formation) is the area near to Ketton.

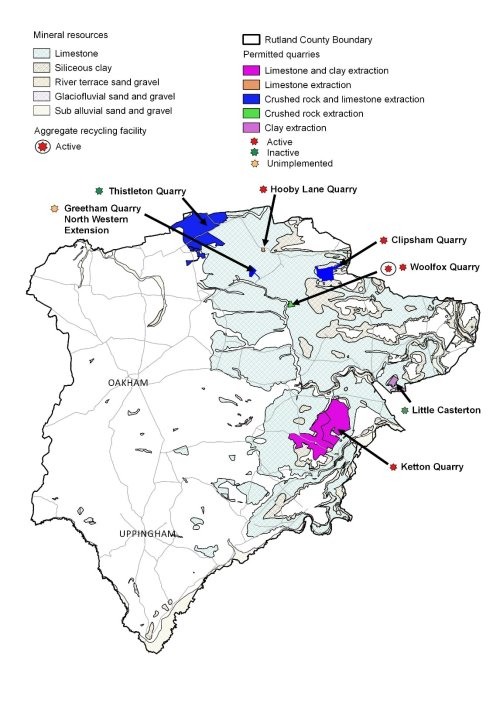

Mineral resources are concentrated almost exclusively in the eastern half of the County and consist mainly of limestone and clay. Some isolated pockets of sand and gravel deposits exist around the edge of the County particularly in the Welland Valley to the south and east of the County. Smaller pockets are found around the River Eye and Whissendine Brook in the north-west, Eye Brook in the west and River Gwash in the north-east, as shown Figure 9.

Minerals development within the County

Within Rutland, both aggregate and non-aggregate minerals are produced. Specific to Rutland this includes limestone as crushed rock (aggregate minerals) and limestone for the purpose of cement manufacture, building / roofing stone and agricultural lime as well as clay for the purpose of brick making and cement manufacture (non-aggregate minerals). Limestone and clay have historically been the main minerals worked in Rutland; this is likely to continue. Ironstone was extracted in the past, but operations ceased in the 1970's and there is no evidence that sand and gravel reserves have ever been worked.

Recycled aggregates are also produced within Rutland; such material can be used to replace the use of primary aggregates (for low specification applications). Other forms of minerals-related development are also found within the County (e.g., associated storage, handling and processing facilities.

Aggregate minerals - Crushed rock (limestone) extraction

Rutland is relatively small in terms of mineral production; in 2022 there were only two active sites for the extraction of crushed rock: Woolfox and Clipsham Quarries[1]. Crushed rock extraction is also permitted at Greetham Quarry North-Western extension and Thistleton Quarry, but operations at these sites have yet to commence. The operation at Thistleton Quarry is pending the construction of a dedicated quarry haul road. The site is an old ironstone permission which, as part of a requirement of the Environment Act 1995, underwent a review to update the old permission with modern planning conditions. As a consequence of the new planning conditions, extraction is now formally for limestone and not ironstone. All four crushed rock quarries are concentrated in an area either side of the A1 within the north-eastern part of the County, near to the Lincolnshire border. Permitted sites are detailed in Appendix 6 with their location and associated geology shown in Figure 9.

The combined permitted reserves of the four sites are 16.2 million tonnes (Mt). This figure relates to when permission was granted and due to subsequent extraction from Woolfox and Clipsham Quarries, this figure is now reduced.

Historically ironstone was extracted to supply the steel works in Corby; however, operations ceased in the 1970's. Three sites have dormant permissions, but these would have to be subject to modern planning conditions before they could operate again. Ironstone is no longer considered to be of economic significance (as a source of iron), although such sites could be worked as a source low quality aggregate or building stone.

Non-aggregate minerals - Limestone and clay extraction

The largest minerals operation in the County is the Heidelberg Materials cement works at Ketton, located in the south-east of the County, close to the Northamptonshire border. It is both a locally and nationally important cement manufacturing plant and relies mainly on locally quarried limestone from the adjacent Grange Top Quarry in conjunction with on-site clays to manufacture around 1.4Mt of cement each year. When the site was granted permission for an extension in 2002 the permitted reserves of limestone and clay were 16.6Mt and 6.2Mt respectively; remaining reserves are now considerably less[2]. Clay extraction is also permitted at Little Casterton (also referred to as Williamson Cliff) located near to the eastern boundary of the County, however the site is currently inactive and extraction is unlikely to resume.

Rutland also produces limestone used as building / roofing stone. These traditional materials play an important role in the restoration of historic buildings and are also used in new buildings, extensions, and walling in order to preserve and enhance local distinctiveness and local building character. In 2022 three quarries in Rutland produced limestone for non-aggregate building stone purposes; Clipsham, Woolfox and Hooby Lane (Stretton). Clipsham and Woolfox quarries also produce limestone for use as agricultural lime in addition to crushed rock. Further, Greetham North-Western extension quarry is permitted for non-aggregate extraction and includes a proportion of limestone for building stone in addition to crushed rock. The extraction of building stone is typically a small-scale operation and over the last 10 years extraction in Rutland has averaged 9,700 tonnes a year. It is understood that there is also building stone suitable for building purposes at Thistleton Quarry, in addition Ketton Quarry has small reserves of freestone. Permitted sites are detailed in Appendix 6 with their location and associated geology shown in Figure 9.

Secondary and recycled aggregates

Currently, a limited amount of recycled aggregates is produced and processed in the County. Rutland has only one permitted site for recycling of inert Construction, Demolition and Excavation (CD&E) waste to produce recycled aggregates. This facility, located within Woolfox Quarry, was operational in 2022. Site details are included in Appendix 6 with the location and associated geology shown in Figure 9. There are currently no secondary aggregates produced or processed in the County.

Figure 9 - Geology of Rutland with location of permitted sites

Spatial Strategy for Minerals Development in Rutland

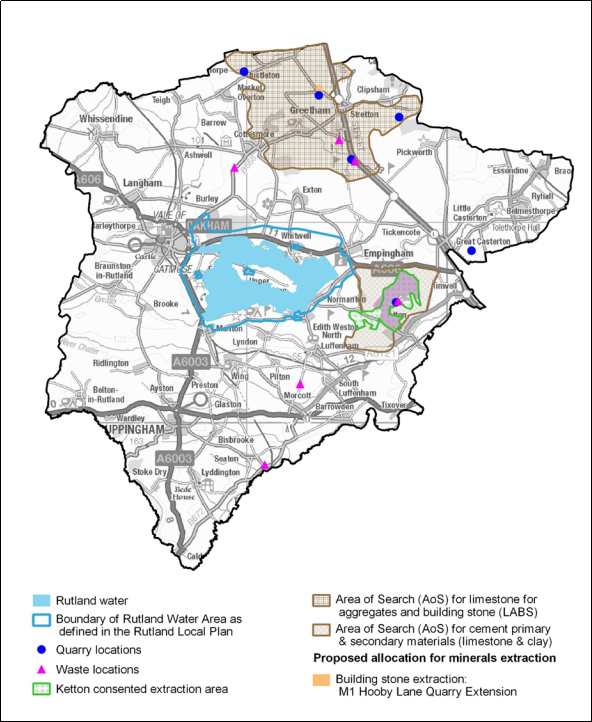

The spatial strategy, as set out in Figure 10, focuses on the eastern part of the County where viable limestone and clay resources are located and have historically been worked. Within the eastern part of the County, the north-east has seen a concentration of sites extracting limestone primarily for aggregate purposes whereas the south-east is dominated by the Ketton Cement Works. Maintaining this distinction between extractive activities will assist in avoiding and/or exacerbating cumulative impacts. Given the variable nature and quality of the resource, it is not possible to specify potential locations for locally sourced building and roofing stone. However, the identification of areas of focus for limestone is considered to provide sufficient guidance regarding building and roofing stone. Historically minerals have not been worked in the western half of the County due to the scarcity of workable mineral deposits.

Aggregate minerals

In order to facilitate delivery of the identified provision rate for crushed rock an Area of Search (AoS) for limestone for aggregate and building stone (LABS) purposes has been identified within the north-east of the County (referred to as the LABS AoS). The LABS AoS focuses on areas of inferred mineral resources (Lincolnshire Limestone) from which extraction has previously, and currently, occurs and so is known to be viable (though it is acknowledged that economic viability may vary within the resource area). The LABS AoS takes in: the area along the County's northern boundary (north of Thistleton); west of Morkery Wood/A1/Stocken Park; south-east of Stretton; south of Clipsham; north-east of Hardwick Wood; north of Exton Park/Westland Wood; and east of Cottesmore and Market Overton. Although the LABS AoS covers a large area, it is not intended that the whole area would be extracted, and it is important to note that the identification of sites within the LABS AoS does not equate to planning permission. The LABS AoS should be viewed as a mechanism to guide industry investment. Any proposal coming forward within the LABS AoS during the plan period would be subject to the planning application process and would need to be compliant with relevant Local Plan policies.

Cement production

Specifically relating to securing adequate provision of mineral resources to maintain cement production at the Ketton cement work, an Area of Search (AoS) for cement primary and secondary materials (limestone and clay) has been identified (referred to as the cement AoS). The cement AoS covers a large area. In order to manufacture good quality cement product, it is essential that the correct balance or "recipe" between the various ingredients is secured and maintained. The recipe is constrained by a number of factors such as quality, location, depth and accessibility. Thus, a large area is required to take account of all these aspects as well as covering both limestone and clay reserves.

The cement AoS takes in the area south of Stamford Road (A606), west of Steadfold Lane, north-west and west of Ketton, north of Ketton Road, north-east of North Luffenham (Edith Weston and Ketton Roads), east of North Luffenham Golf Club (including the eastern section of the disused North Luffenham Airfield) and east of Woodside Farm/south-east of Coach Road Farm. Whilst the whole of the cement AoS is shown for exploration purposes, any detailed working proposals to extract minerals need to be sufficient to maintain a stock of permitted reserves of at least 15 years. This does not mean that the whole area will be extracted. Given the current reserve position at the Ketton site, it is likely that a planning application will come forward within the cement AoS during the plan period to secure additional reserves for the cement works. Industry has confirmed that the cement AoS is sufficient to secure 15 years stock.

Recycled aggregates

Primary aggregates should be put to the highest quality end use, where possible recycled and secondary aggregates should be used in place of primary aggregates in order to conserve resources, minimise waste and contribute to the move to a low carbon economy. An increase in the consumption, and production, of recycled and secondary aggregates is supported through the Local Plan.

Facilities for the recycling of aggregates are not linked to geological conditions and so can be directed to more appropriate locations. The location of such development should be in line with the spatial strategy for waste management which sets a preference for development within industrial areas, existing waste sites and where associated with the re-use of previously development land (Policy MIN1), including as an ancillary activity on existing mineral extraction sites or disused railheads and wharves.

The spatial strategy does not take into consideration potential adverse impacts and other parameters that may affect the built and natural environment or communities; such matters are addressed at an appropriate level through relevant Local Plan policy. Land ownership constraints are also not taken into account and are the proponent's responsibility to address. It should be noted that the identification of areas within the spatial strategy does not imply grant of planning permission, any proposal would be required to be assessed through the Development Assessment process and comply with the Local Plan policies.

Figure 10 – The spatial strategy for mineral extraction and proposed allocation for mineral extraction

Supporting evidence

Minerals Spatial Strategy (October 2023)

[1] A southern extension to Clipsham Quarry was permitted in 2020 however both the original quarry and southern extension are classified as one site due to both sites being worked simultaneously by the same operator and combined reporting of reserve and sales figures.

[2] Figures cannot be published for confidentiality reasons.