Regulation 18 draft Local Plan

(18) Chapter 10 - Minerals and Waste

Minerals

As the Minerals Planning Authority (MPA), Rutland is responsible for setting out the spatial strategy for mineral extraction in the County, defining Mineral Safeguarding Areas, identifying the provision of minerals to be met in Rutland over the plan period; planning for this provision by identifying sufficient opportunities for extraction; and setting out development criteria against which planning applications will be assessed.

Spatial Strategy for Minerals Development

What will the policy do?

The Mineral Spatial Strategy will set out where new minerals development should be located, including both mineral extraction and facilities for the processing of recycled aggregates. This is necessary to guide future mineral development and investment.

(8) Policy MIN1 - Spatial strategy for minerals development

Extraction of mineral resources, in particular limestone for aggregate purposes and limestone and clay for cement purposes, will be focussed within the:

- Limestone for aggregates and building stone Area of Search (AoS), and

- Cement primary and secondary materials AoS.

Small-scale extraction of non-aggregate minerals for building/roofing stone and clay, where linked to historic environment conservation outcomes, will be supported in rural areas or within settlements.

Recycled aggregate facilities should be in general conformity with the spatial strategy and development principles for waste management and disposal (Policy WST1).

Why is this policy needed?

National policy recognises that minerals are essential to support sustainable economic growth and our quality of life. However, as minerals are finite natural resources and can only be worked where they are found, it is important to make best use of them to secure their long-term conservation.

The NPPF states that Minerals Planning Authorities (MPAs) should plan for a steady and adequate supply of minerals of economic importance by identifying in their Local Plans, sites and/or areas for minerals extraction in appropriate locations. The Government also encourages MPAs to take account of the contribution that secondary and recycled materials can make to the supply of materials in preference to the extraction of primary materials as part of a circular economy.

It is important to note that minerals can only be worked where they are found, however where possible the Plan seeks to relate minerals development with growth or market areas and to reflect local circumstance such as features of significance, in particular Rutland Water and Ketton Cement Works. Within Rutland, minerals considered to be of economic importance for aggregate purposes include limestone and for non-aggregate purposes include limestone and clay. Recycled aggregates (inert CD&E – Construction, Demolition and Excavation - waste) are also produced within Rutland.

Geology of Rutland

The particular geology of the area has given its name to the Rutland Formation which was formed from muds and sand carried down by rivers and occurring as bands of different colours, each with many fossil shells at the bottom. At the bottom of the Rutland Formation is a bed of dirty white sandy silt. Under the Rutland Formation is a formation called the Lincolnshire Limestone. The best exposure of this limestone (and also the Rutland Formation) is the area near to Ketton.

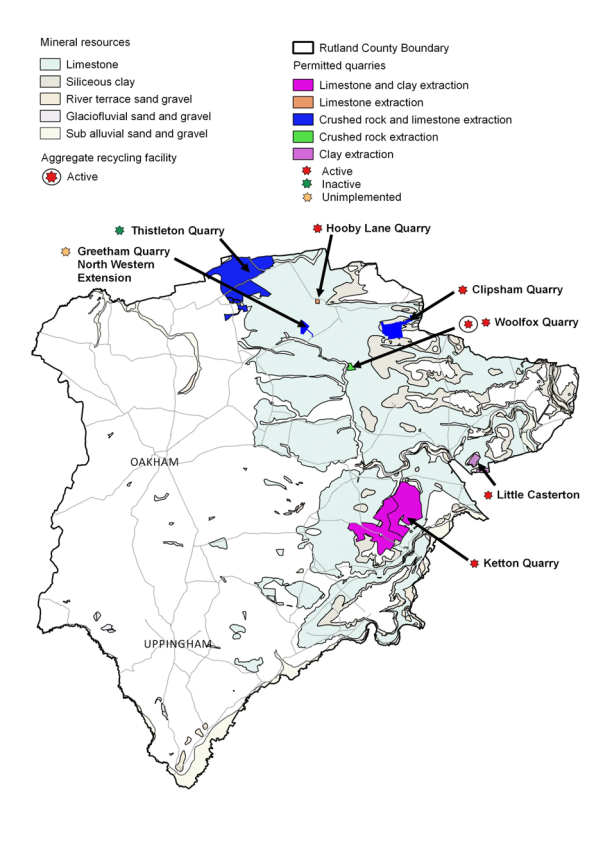

Mineral resources are concentrated almost exclusively in the eastern half of the County and consist mainly of limestone and clay. Some isolated pockets of sand and gravel deposits exist around the edge of the County particularly in the Welland Valley to the south and east of the County. Smaller pockets are found around the River Eye and Whissendine Brook in the north-west, Eye Brook in the west and River Gwash in the north-east, as shown Figure 7.

Minerals development within the County

Within Rutland, both aggregate and non-aggregate minerals are produced. Specific to Rutland this includes limestone as crushed rock (aggregate minerals) and limestone for the purpose of cement manufacture, building / roofing stone and agricultural lime as well as clay for the purpose of brick making and cement manufacture (non-aggregate minerals). Limestone and clay have historically been the main minerals worked in Rutland; this is likely to continue. Ironstone was extracted in the past, but operations ceased in the 1970's and there is no evidence that sand and gravel reserves have ever been worked.

Recycled aggregates are also produced within Rutland; such material can be used to replace the use of primary aggregates (for low specification applications). Other forms of minerals-related development are also found within the County (e.g., associated storage, handling and processing facilities.

Aggregate minerals - Crushed rock (limestone) extraction

Rutland is relatively small in terms of mineral production; in 2022 there were only two active sites for the extraction of crushed rock: Woolfox and Clipsham Quarries[1]. Crushed rock extraction is also permitted at Greetham Quarry North-Western extension and Thistleton Quarry, but operations at these sites have yet to commence. The operation at Thistleton Quarry is pending the construction of a dedicated quarry haul road. The site is an old ironstone permission which, as part of a requirement of the Environment Act 1995, underwent a review to update the old permission with modern planning conditions. As a consequence of the new planning conditions, extraction is now formally for limestone and not ironstone. All four crushed rock quarries are concentrated in an area either side of the A1 within the north-eastern part of the County, near to the Lincolnshire border. Permitted sites are detailed in Appendix 6 with their location and associated geology shown in Figure 7

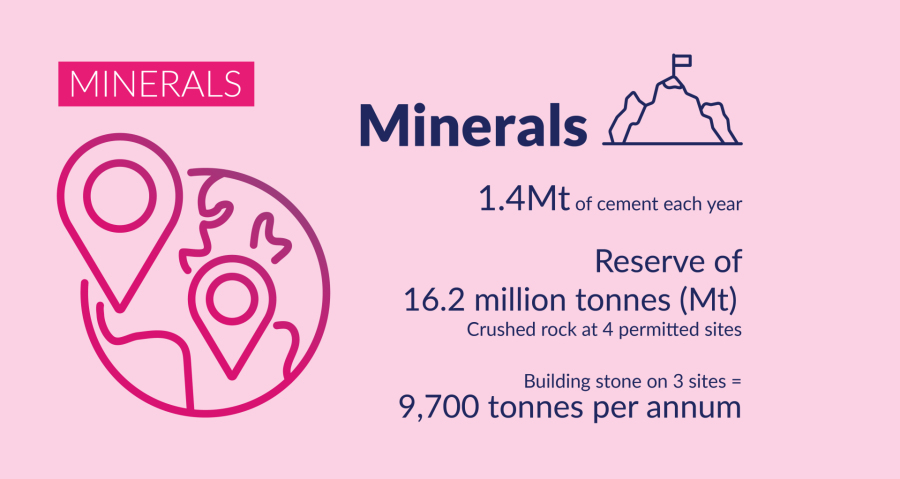

The combined permitted reserves of the four sites are 16.2 million tonnes (Mt). This figure relates to when permission was granted and due to subsequent extraction from Woolfox and Clipsham Quarries, this figure is now reduced.

Historically ironstone was extracted to supply the steel works in Corby; however, operations ceased in the 1970's. Three sites have dormant permissions, but these would have to be subject to modern planning conditions before they could operate again. Ironstone is no longer considered to be of economic significance (as a source of iron), although such sites could be worked as a source low quality aggregate or building stone.

Non-aggregate minerals - Limestone and clay extraction

The largest minerals operation in the County is the Heidelberg Materials cement works at Ketton, located in the south-east of the County, close to the Northamptonshire border. It is both a locally and nationally important cement manufacturing plant and relies mainly on locally quarried limestone from the adjacent Grange Top Quarry in conjunction with on-site clays to manufacture around 1.4Mt of cement each year. When the site was granted permission for an extension in 2002 the permitted reserves of limestone and clay were 16.6Mt and 6.2Mt respectively; remaining reserves are now considerably less[2] . Clay extraction is also permitted at Little Casterton (also referred to as Williamson Cliff) located near to the eastern boundary of the County. Operations are currently active and of a small scale with the site worked only a few times a year. Fireclays from the site are exported and used in the making of a specialist brick - Little Casterton facing brick - that is used to repair listed buildings. Rutland also produces limestone used as building / roofing stone and agricultural lime. In 2022 three quarries in Rutland produced limestone for non-aggregate building stone purposes; Clipsham, Woolfox and Hooby Lane (Stretton). Clipsham and Woolfox quarries also produce limestone for use as agricultural lime in addition to crushed rock. Further, Greetham North-Western extension quarry is permitted for non-aggregate extraction and includes a proportion of limestone for building stone in addition to crushed rock. The extraction of building stone is typically a small-scale operation and on average the three active sites combined produce approximately 9,700 tonnes a year. It is understood that there is also building stone suitable for building purposes at Thistleton Quarry, in addition Ketton Quarry has small reserves of freestone. Permitted sites are detailed in Appendix 9 with their location and associated geology shown in Figure 5.

Secondary and recycled aggregates

Currently, a limited amount of recycled aggregates is produced and processed in the County. Rutland has only one permitted site for recycling of inert Construction, Demolition and Excavation (CD&E) waste to produce recycled aggregates. This facility, located within Woolfox Quarry, was operational in 2022. Site details are included in Appendix 6 with the location and associated geology shown in Figure 7. There are currently no secondary aggregates produced or processed in the County.

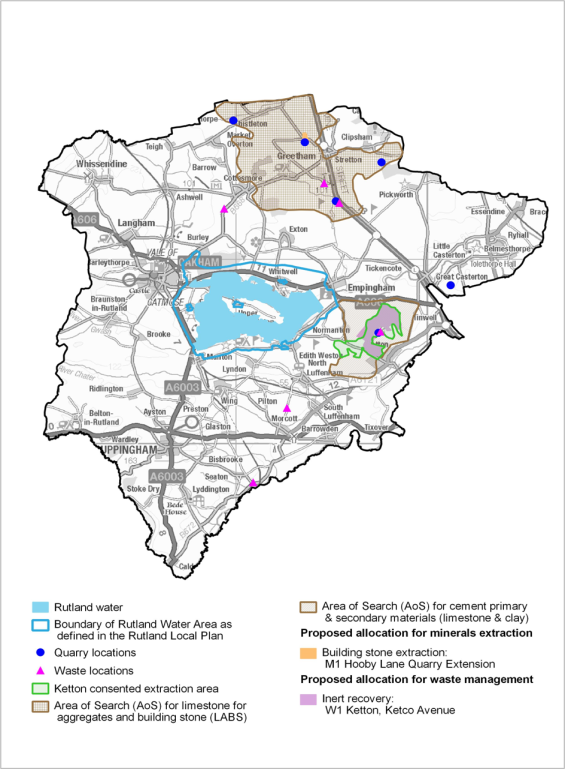

Figure 7: Geology of Rutland with location of permitted sites

Spatial Strategy for Minerals Development in Rutland

The spatial strategy focuses on the eastern part of the County where viable limestone and clay resources are located and have historically been worked. Within the eastern part of the County, the north-east has seen a concentration of sites extracting limestone primarily for aggregate purposes whereas the south-east is dominated by the Ketton Cement Works. Maintaining this distinction between extractive activities will assist in avoiding and/or exacerbating cumulative impacts. Given the variable nature and quality of the resource, it is not possible to specify potential locations for locally sourced building and roofing stone. However, the identification of areas of focus for limestone is considered to provide sufficient guidance regarding building and roofing stone. Historically minerals have not been worked in the western half of the County due to the scarcity of workable mineral deposits.

Aggregate minerals

In order to facilitate delivery of the identified provision rate for crushed rock an Area of Search (AoS) for limestone for aggregate and building stone (LABS) purposes has been identified within the north-east of the County (referred to as the LABS AoS). The LABS AoS focuses on areas of inferred mineral resources (Lincolnshire Limestone) from which extraction has previously, and currently, occurs and so is known to be viable (though it is acknowledged that economic viability may vary within the resource area). The LABS AoS takes in: the area along the County's northern boundary (north of Thistleton); west of Morkery Wood/A1/Stocken Park; south-east of Stretton; south of Clipsham; north-east of Hardwick Wood; north of Exton Park/Westland Wood; and east of Cottesmore and Market Overton. Although the LABS AoS covers a large area, it is not intended that the whole area would be extracted, and it is important to note that the identification of sites within the LABS AoS does not equate to planning permission. The LABS AoS should be viewed as a mechanism to guide industry investment. Any proposal coming forward within the LABS AoS during the plan period would be subject to the planning application process and would need to be compliant with relevant Local Plan policies.

Cement production

Specifically relating to securing adequate provision of mineral resources to maintain cement production at the Ketton cement work, an Area of Search (AoS) for cement primary and secondary materials (limestone and clay) has been identified (referred to as the cement AoS). The cement AoS covers a large area. In order to manufacture good quality cement product, it is essential that the correct balance or "recipe" between the various ingredients is secured and maintained. The recipe is constrained by a number of factors such as quality, location, depth and accessibility. Thus, a large area is required to take account of all these aspects as well as covering both limestone and clay reserves.

The cement AoS takes in the area south of Stamford Road (A606), west of Steadfold Lane, north-west and west of Ketton, north of Ketton Road, north-east of North Luffenham (Edith Weston and Ketton Roads), east of former North Luffenham Gold Club (including the eastern section of the disused North Luffenham Airfield) and east of Woodside Farm/south-east of Coach Road Farm. Whilst the whole of the cement AoS is shown for exploration purposes, any detailed working proposals to extract minerals need to be sufficient to maintain a stock of permitted reserves of at least 15 years. This does not mean that the whole area will be extracted. Given the current reserve position at the Ketton site, it is likely that a planning application will come forward within the cement AoS during the plan period to secure additional reserves for the cement works. Industry has confirmed that the cement AoS is sufficient to secure 15 years stock.

Recycled aggregates

Primary aggregates should be put to the highest quality end use, where possible recycled and secondary aggregates should be used in place of primary aggregates in order to conserve resources, minimise waste and contribute to the move to a low carbon economy. An increase in the consumption, and production, of recycled and secondary aggregates is supported through the Local Plan.

Facilities for the recycling of aggregates are not linked to geological conditions and so can be directed to more appropriate locations. The location of such development should be in line with the spatial strategy for waste management which sets a preference for development within industrial areas, existing waste sites and where associated with the re-use of previously development land (Policy MIN1), including as an ancillary activity on existing mineral extraction sites or disused railheads and wharves.

The spatial strategy does not take into consideration potential adverse impacts and other parameters that may affect the built and natural environment or communities; such matters are addressed at an appropriate level through relevant Local Plan policy. Land ownership constraints are also not taken into account and are the proponent's responsibility to address. It should be noted that the identification of areas within the spatial strategy does not imply grant of planning permission, any proposal would be required to be assessed through the Development Assessment process and comply with the Local Plan policies.

What you told us about the topic

The Issues and Options consultation asked about efficient and sustainable use of, and supply and demand for, minerals under Issue 11. You told us you supported the use of recycled aggregate as alternatives to primary aggregates, being the more sustainable option, and the production of cement an essential product. Respondents also highlighted the potential for cumulative impacts with a concentration of extraction in the east of Rutland and raised concerns over the impact of cement production on climate change.

As a result of the consultation, the plan supports the use of recycled and secondary aggregates in place of primary aggregates where possible and identifies a cement AoS. The approach of maintaining the distinction between extractive activities in the north-east and south-east, will assist in avoiding and/or exacerbating cumulative impacts, and is reported in the Spatial Strategy report. Until/if there is a change in national regulations/guidance in relation to cement production and decarbonisation, then the plan preparation will continue in line with the current national guidance.

What alternatives have we considered?

Identifying specific sites for mineral extraction and secondary or recycled aggregate production.

Which existing policies will be replaced by this policy?

MCS3 - General Locational Criteria

MCS4 - Ketton Quarry Area of Search

MCS11 - Recycled and Secondary Aggregates

MDC9 - Recycled and Substitute materials

MCS6 - Building and Roofing Stone

MCS7 - Residential and Sensitive Land Uses

Mineral provision

What will the policy do?

The Plan will seek to secure a provision of 0.28 million tonnes per annum (Mtpa) of crushed rock (limestone) and maintain a sufficient stock of permitted reserves for limestone and clay in order to supply the Cement Works at Ketton at an output of around 1.4 million tonnes (Mt).

Annual provision figures for building / roofing stone and clay are not identified in the Plan given the relatively low level of output and that there is no requirement to identify a rate. However, such resources, particularly relating to Ketton Stone and Clipsham Stone, are recognised as being of importance for the repair and maintenance of heritage sites and in protecting designated sites.

A landbank is a stock of planning permissions for mineral extraction and is calculated by dividing the permitted reserves by the provision rate. A landbank of at least 10 years for crushed rock, and a stock of permitted reserves of at least 15 years for cement primary and secondary materials (limestone and clay), will be sought.

The provision of minerals has been taken forward in the Plan through the identification of an annual aggregate provision rate, an aggregate landbank target, seeking to provide a stock of permitted reserves to maintain cement production, spatial strategy and locational criteria for minerals related development, site-specific allocations, development management policies, as well as safeguarding mechanisms.

(8) Policy MIN2 - Mineral provision

In providing a steady and adequate supply of minerals over the plan period 2021 to 2041 the plan will seek to:

- make provision for the extraction of 5.6 million tonnes of crushed rock (limestone), equivalent to an annual average of 0.28 million tonnes.

- maintain a sufficient stock of permitted reserves for limestone and clay in order to supply the Cement Works at Ketton at an output of around 1.4 million tonnes of cement production per annum.

- support the supply of minerals where necessary for conservation purpose and / or maintaining the local distinctiveness of the built environment within Rutland.

The maintenance of a landbank of at least 10 years for crushed rock will be sought.

A stock of permitted reserves of at least 15 years for cement primary and secondary materials (limestone and clay) will be sought.

This will be delivered through existing sites and new sites (including allocated and unallocated sites where in compliance with relevant local plan polices) as well as the identification of the cement primary and secondary materials Area of Search.

Why is this policy needed?

MPAs are required by national policy to make provision for a steady and adequate supply of minerals. In line with government requirements, the Council prepares an annual Local Aggregates Assessment (LAA) - this involves participation in and taking account of advice of Aggregate Working Parties (AWP). Through these mechanisms the Council has also co-operated with other MPAs with respect to minerals planning for cement production to ensure adequate provision is made. Advice of the National Aggregate Co-ordinating Group (NACG) and published National and sub-national Guidelines on future provision are also taken into account as appropriate.

Aggregate provision

MPAs are required to calculate their own provision rates on the basis of average aggregate sales over a ten-year rolling period and other relevant information. This method of calculation replaces the previous sub-regional approach to apportionment where a nationally prescribed regional apportionment figure was sub-divided within each region. Historically, Rutland and Leicestershire had a joint sub-regional apportionment figure, however this is not prescribed.

The LAA reports on the rolling average of ten years sales data, other relevant local information and an assessment of all supply options. The 2023 LAA informed the Plan's aggregate provision rate.

The Plan will seek to secure a provision of 0.28 million tonnes per annum (Mtpa) of crushed rock (limestone). This provision rate is calculated on the basis of average aggregate sales over a 10-year rolling period (2013 – 2022) and consideration of local circumstance. Further detail is set out in the 2023, and subsequent LAAs.

It is not likely that the demand for crushed rock in Rutland will be any greater than that experienced previously and as such it is not necessary to factor in any additional growth to a provision rate. In addition, there are no major infrastructure projects planned in the County that would result in a significant increase in demand for mineral resources. The level of aggregate demand/supply and landbanks will be monitored through the Local Plan monitoring framework and LAA.

To ensure a steady and adequate supply of minerals, and not inflate annual extraction rates above those which have been allowed for in sales projections, annual sales can be limited by limiting the number of HGV movements at certain sites. Where this doesn't apply, there is an expectation that operators will complete extraction over the timescale specified in the planning application and not sooner.

Movement of Aggregates

Imports and exports of aggregates are reported through the national Aggregate Monitoring Survey (AMS). The latest survey (2019) reports export data for Rutland separately, however imports are combined with Leicestershire as one sub-region.

Crushed rock produced within the sub-region in 2019 totalled 14.1Mt of which just under a half (around 6.1Mt) remained within the sub-region. Specific to Rutland, information on mineral movements in 2019 is limited. 42% of crushed rock produced was exported to the East Midlands region however the remainder was sold to either an unknown destination or not allocated a destination. Mineral movements data is more complete for the previous survey in 2014 and of the crushed rock produced, the majority was used within the sub-region (28%) or exported to Northamptonshire (26%). The remaining crushed rock was exported to other sub-regions within the East Midlands or to the East of England. This reflects the proximity of Rutland to these areas.

Overall movements of crushed rock into and out of the sub-region are not self-balancing and the sub-region is a (major) net exporter of crushed rock. This reflects the strategic location of the sub-region and the fact that Leicestershire has traditionally been a large supplier of crushed rock (igneous rock). Leicestershire has several nationally important quarries that are significant producers of igneous rock. There is limited demand in Rutland for such aggregate to supply major construction projects, this is reflected in the amount of exports and indicates that demand for aggregate is from further afield.

Through the identification of a crushed rock provision rate the Plan seeks to encourage the continued supply of crushed rock to support growth both within and outside the County.

The sub-region imported 0.36Mt of crushed rock in 2019 from a range of areas including the West Midlands and East Midlands.

Sand and gravel are not produced within Rutland and as such the County is a net importer. The 2019 AMS identifies that 0.687Mt of sand and gravel was imported into the sub-region. As Rutland has limited sand and gravel resources and the mineral has not historically been quarried, the County will continue to rely on imports from other areas. Further detail on movements of aggregates is set out the Local Aggregates Assessment (LAA).

Non-aggregate provision

Regarding cement production, national policy requires the plan to provide a stock of permitted reserves to support the maintenance of cement production of at least 15 years. Ketton Cement Works has an annual output of around 1.4Mt of cement. Recent production levels have been around 1.4Mt or just below which indicates there is no need to increase the output further.

Landbanks

The Government requires MPAs to have landbanks for aggregates and raw industrial minerals such as limestone and clay for cement manufacture. Landbanks are principally a monitoring tool to provide an early indication of possible disruption to the provision of an adequate and steady supply of mineral in the County and indicate when new permissions are likely to be needed. Government policy requires provision to be made for the maintenance of landbanks of at least 10 years for crushed rock and provision of a stock of permitted reserves to support maintenance of cement production of at least 15 years for cement primary and secondary materials to maintain an existing plant.

Based on the 0.28 Mtpa provision rate for crushed rock, the maintenance of crushed rock landbanks at the end of the plan period equates to an additional 2.8Mt. At the commencement of the plan period the crushed rock landbank for Rutland is approximately 39 years. Rutland therefore has sufficient reserves to provide a 10-year landbank.

Ketton Cement Works has an annual output of around 1.4Mt of cement and at this rate there are sufficient permitted reserves to carry operations through to around the middle of the plan period but not up to 15 years. It is likely therefore that the cement works will need to secure additional reserves before the plan period ends. The need to secure additional reserves is recognised and encouraged in the Plan through Policy MIN2.

What you told us about the topic

The Issues and Options consultation asked about the supply and demand for minerals under Issue 11. Respondents suggested the Plan should: support the supply of building stone for use in historic and new buildings and cement production at Ketton and be sufficiently flexible to enable any unforeseen demand for minerals to be met. You also told us that the amount of extraction should be proportionate to the size of the County, for extraction to primarily meet local and regional demand, and to set limits on aggregate sales.

As a result of the consultation responses, Policy MIN2 supports the provision of minerals where linked to historic conservation/maintaining the local distinctiveness of the built environment and cement production at Ketton at an output of around 1.4 Mtpa. There is sufficient flexibility built into the plan to enable demand to be met from existing sites and new sites (including allocated and unallocated sites). Any proposal for extraction will be required to take into account the current reserve and supply position, provision rate (where relevant) and landbanks, which are monitored and reported annually in the LAA. Included in the supporting policy text is reference to limits on annual sales to ensure quarries are not overworked, with more mineral extracted annually than originally planned.

Safeguarding Rutland's Mineral Resources

What will the policy do?

Minerals Safeguarding Areas (MSAs) have been defined to protect mineral resources of local and national importance including limestone, clay and river terrace sand and gravel resources, from unnecessary sterilisation.

(5) Policy MIN3 Safeguarding Rutland's mineral resources

Mineral Safeguarding Areas (MSAs) have been designated to safeguard mineral resources of local and national importance from unnecessary sterilisation by other development; these include:

- limestone and ooidal freestones resources from the Lincolnshire limestone formation;

- siliceous clay resources from the Rutland formation and fireclay; and

- river terrace sand and gravel resources associated with the River Gwash and River Welland as well as the West Glen River, River Chater, Eye Brook, a tributary of the River Eye and Rutland Water.

Planning permission will not be granted for non-mineral development that would lead to the unnecessary sterilisation of mineral resources within a Minerals Safeguarding Area unless it can be demonstrated that:

- the mineral concerned is not of economic value or evidence confirms the absence of mineral resources, or

- the proposed development is temporary or of a nature that would not sterilise the mineral resource or hinder future extraction, or

- prior extraction can occur where practicable, environmentally feasible and within a reasonable timescale, or

- there is an over-riding need for the development, or

- the development is exempt.

In determining the need for prior extraction an assessment of the following factors will be required to inform the decision-making process:

- site-specific geological survey data (in addition to the Councils MSA and British Geological Survey mapping data) to establish the existence or otherwise of mineral resources setting out the type, quality, quantity, extent of the resource, overburden to reserve ratio, the proportion of the mineral to be used on-site and estimated saleable mineral;

- economic viability and practicability of prior extraction, this should also take account of the size, nature and need for the (non-minerals) development as well as the proposed phasing of operations and construction of the non-mineral development; and

- potential environmental impacts resulting from prior extraction.

Where the non-mineral development is delayed or not implemented the site must be restored to a stable landform and appropriate after-use that would not hinder future extraction.

Why is this policy needed?

National policy requires identification of MSAs and complementary policies to prevent the needless sterilisation of minerals resources of local and national importance (by non-mineral development). Minerals are an important finite natural resource that can only be extracted where they naturally occur. This means that it is necessary to consider protecting minerals from non-minerals development to ensure that future generations are able to access such resources.

Limestone resources from the Lincolnshire limestone formation are used for both aggregate as crushed rock and non-aggregate purposes as cement primary materials and building / roofing stone. Resources for building stone identified as being of local and national importance in accordance with Historic England's Strategic Stone Study (2011) include Ketton Stone and Clipsham Stone (ooidal freestones from the Upper Lincolnshire limestone member). Clay resources around Ketton are used in cement production with a small amount at Little Casterton used in the production of bricks to repair listed buildings. Clay resources identified as being of local importance include siliceous clays from the Rutland formation and fireclay.

The identification of MSAs does not necessarily mean that these areas will be worked in the future. MSAs, and corresponding Minerals Consultation Areas[3] (MCAs), should be viewed as a signpost to indicate the presence of mineral resources and as a trigger for such issues to be considered in the decision-making processes for land-use planning, including consultation where non-minerals development is proposed.

It is important to bear in mind that just because there may be no interest in particular resources now, this may not continue to be the case in the future. There are limited river terrace sand and gravel resources identified within Rutland that, although not currently of interest or previously worked, are typically recognised in other areas to be of importance. Future generations may find a requirement for such materials and so it is reasonable for these to be included in the MSAs. River terrace sand and gravel resources identified within Rutland are associated with the River Gwash and River Welland as well as the West Glen River, River Chater, Eye Brook, a tributary of the River Eye and Rutland Water.

Glacial sand and gravel and ironstone resources within the County are not currently worked and are not considered to be viable; it is unlikely that this will change in the long term. As such these resources are not included in the MSAs as they are not considered to be of local or national importance.

As a unitary authority, Rutland County Council is responsible for undertaking consultation with regards to proposals for non-mineral development within identified MCAs, consultation will occur: (i) within Council; (ii) between Council and developers; and (iii) between Council and other authorities (for example where a proposal within an adjoining authority's boundary may impact mineral interests within Rutland, or vice versa). The purpose of which is to ensure that mineral interests are taken into account early in the decision-making process and to discuss the economic viability of the mineral resource and whether prior extraction of the resource is appropriate in order to avoid sterilisation.

The MSAs (and MCAs) are shown on the Policies Map.

It is not necessary to consult on every development proposal; this is because some development represents a lower potential for sterilisation or would not present the opportunity for prior extraction. Accordingly, the following surface development is exempt from consultation and developer requirements relating to MSA/MCAs:

- extensions to existing dwelling houses and other householder planning applications (except for new dwellings),

- provision of dwelling house(s): (i) within the built-up area - less than 10 dwelling houses, or a site area of less than 0.5 ha; or (iii) elsewhere - one dwelling house within the recognised Planned Limits of Development boundary,

- minor extension or alteration to an existing building,

- development (other than the provision of dwelling houses) on a site having an area of 1 ha or more within the built-up area;

- changes of use, advertisement consent, amendments to previously approved applications/current permissions (with no additional land take involved), reserved matters, prior notifications, certificates of lawfulness of existing use or development, certificate of lawfulness of proposed use or development, works to trees and other miscellaneous minor works/applications (e.g., fences, gates, access, etc.).

Prior extraction of minerals is encouraged, where practicable and environmentally feasible, if it is necessary for non-mineral development to take place. A realistic judgment about the resource viability, practicability and potential environmental impacts will be made; the MPA will not seek to prevent development where it is unlikely that prior extraction is feasible.

Assessment should include the following: (i) site-specific geological survey data; (ii) practicability of prior extraction; and (iii) potential environmental impacts resulting from prior extraction. Preparation of the assessment is the responsibly of the developer and is to accompany the planning application for the non-mineral development. The Council will make a judgement on the need for prior extraction before determination of the application for non-minerals development. A separate planning application (to the non-minerals development) will be required for the prior extraction of mineral resources, which will be determined in accordance with Policy MIN4 Development criteria for mineral extraction, as well as all other relevant Local Plan policies. The non-minerals development should not proceed before the mineral is extracted or steps taken to avoid sterilisation.

What you told us about the topic

The Issues and Options consultation asked about the safeguarding of mineral resources and infrastructure under Issue 11. Respondents suggested that limestone aggregate, building stone, clay and limestone (for use in cement manufacture), and sand and gravel be safeguarded. The majority (70%) of respondents who commented on the extent of the defined MSAs, agreed the MSAs should exclude built up areas. Most of the respondents who commented on MSA buffer zones wanted buffers around MSAs, and it was suggested a 250m buffer be applied to all mineral resources.

The methodology for identifying MSAs includes minerals resources in Rutland of local and/or national importance, i.e., limestone, clay and river terrace sand and gravel, and urban, built-up, areas to reflect mineral resources are present, possibly allowing for future extraction, where associated with large redevelopments. Buffers will be applied around all mineral resources in creating the MSAs. This will help to account for encroachment of non-minerals development that could potentially result in sterilisation of the resource. The proposed buffers are: 500 metres (m) for limestone; 250m for clay; and 250m for sand and gravel. Further detail for establishing these buffers is set out in the methodology.

What alternatives have we considered?

Identified resource areas without buffers

Including built-up areas in MSAs

Which existing policies will be replaced by this policy?

MCS10 - Minerals Safeguarding

MDC10 - Development in Mineral Safeguarding Areas

Minerals Development

What will the policy do?

The policy provides a range of development and assessment criteria which proposals for minerals development must satisfy before planning permission is granted. These are required because the identification of areas through the spatial strategy for minerals development does not mean that planning permission will automatically be granted for proposals that come forward in these areas; this applies equally to allocated sites.

(18) Policy MIN4 - Development criteria for mineral extraction

Proposals for extraction of minerals will be permitted where it can be demonstrated that the development:

- complies with the spatial strategy for minerals set out in Policy MIN1 and relevant Local Plan policies;

- is required to maintain a sufficient supply of material with respect to:

- The adopted aggregate provision rate and/or the maintenance of a landbank, or

- The adopted cement production rate and/or maintaining a stock of permitted reserves for cement materials, or

- Supporting conservation of the historic environment or maintaining the local distinctiveness of the built environment within Rutland;

- maximises the recovery of the reserve whilst minimising waste;

- promotes the most appropriate end-use of materials; and

- is environmentally acceptable and avoids and/or minimises potentially adverse impacts (including cumulative impacts) to acceptable levels.

Proposals for the extraction of minerals to support conservation of the historic environment or maintaining local distinctiveness must demonstrate that this is the main purpose of the proposal.

Preference will be given to proposals for mineral extraction at allocated sites. Proposals on unallocated sites or outside of the areas identified in the spatial strategy will be considered where:

- the proposal relates to extraction of aggregates or cement materials (limestone and clay) and cannot reasonably or would not otherwise be met from committed or allocated reserves, or from within the cement primary and secondary materials Area of Search; or

- extraction of the mineral can be clearly demonstrated to be ancillary to the proposed development (e.g., agricultural reservoirs); or

- the proposal is for the prior extraction within a Mineral Safeguarding Area.

Proposals for minerals development must be expected to: identify and determine the nature and extent of potentially adverse impacts likely to result from the development and demonstrate how the proposal will protect local amenity, particularly in relation to dust, noise and vibration; secure safe and appropriate site access; and make provision to secure highway safety.

Where potentially adverse impacts are likely to occur appropriate mitigation measures must be identified to avoid and/or minimise impacts to an acceptable level. Where applicable a site-specific management plan should be developed to ensure the implementation and maintenance of such measures throughout construction, operation, decommissioning and restoration works.

Why is this policy needed?

National policy requires proposals for mineral extraction to be environmentally acceptable and avoid and/or minimise potentially adverse impacts to acceptable levels. This includes impacts on the natural and historic environment and on human health, including from noise, dust, visual intrusion, traffic, tip and quarry slope stability, differential settlement of quarry backfill, mining subsidence, increased flood risk, impacts on the flow and quantity of surface and groundwater and migration of contamination from the site. Any assessment of potential adverse impacts should also take into account cumulative effects. It is expected that monitoring of planning conditions related to adverse impacts . will be undertaken to the highest possible standards to address the risk to health of nearby residents and the neighbouring environment generally.

In line with government requirements, MPAs are required to make provision for a steady and adequate supply of minerals, therefore any proposal for extraction of aggregates or cement primary and secondary materials (limestone and clay) will be required to take into account the current reserve and supply position, identified provision rate or requirement to maintain a sufficient stock of cement production materials (as appropriate), maintenance of landbanks or stock of permitted reserves for cement production materials (as appropriate) and where the proposal is for an unallocated site why the need cannot reasonably or would not otherwise be met from committed or allocated reserves. Proposals that come forward that would result in supply exceeding the identified provision rate or cement production rate will need to demonstrate that the proposed over-supply is supported by the latest LAA (for crushed rock); or is supported by the cement plant and that the current landbank is below 15 years (for cement production materials).

Specifically, regarding the Ketton cement works, the location of the cement works and associated extraction areas is within an area of intensive quarrying which has already significantly altered the landscape. Any proposals for extending mineral extraction in relation to cement manufacture will need to address what measures can reasonably be taken to improve the general visual amenity and landscape of the area within the operator's ownership and/or control and to ensure that potentially adverse impacts affecting people and local communities are avoided and/or minimised to acceptable levels.

Any proposal for mineral extraction associated with the Ketton cement works will need to include, in addition to other requirements set out through the Local Plan policies:

- appropriate archaeological investigation at a pre-determination stage.

- provision for the retention or suitable temporary diversion of the Hereward Way, Macmillan Way and the Rutland Round and any public right of way that would be affected.

- the provision of suitable measures to ensure the conservation and enhancement of the special features of interest of Shacklewell Hollow and North Luffenham Quarry Sites of Special Scientific Interest.

- the provision of suitable measures to protect and where appropriate enhance: trees, woodland and other landscape features within and adjoining the site; watercourses crossing the site; and groundwater abstractions present in the locality - unless the need for, and benefits of, the development in that location outweigh the likely loss or damage, in which case appropriate mitigation or compensation measure should be provided.

- the provision of suitable measures to protect the Windmill, off Empingham Road, Ketton and its setting.

What you told us about the topic

In Issue 11 of the Issues and Options consultation we asked about how best to manage the impact of mineral development. 54% of those responding to this question agreed that the Plan should include specific policies for managing the impacts of mineral development on the wider environment and restoration/after-use of mineral workings. You told us how it is important for the plan to seek to prevent any unacceptable impacts from mineral extraction and how there should be buffer zones preventing quarries coming too close to residential areas and community facilities.

As a result of the consultation responses, Policy MIN4 is tailored specific to minerals development to ensure sites for mineral extraction are developed in the most sustainable and appropriate locations and manage the impacts of mineral development, including the requirement for appropriate mitigation measures to be identified to avoid and/or minimise impacts to an acceptable level. Separation distances between a quarry and residential areas are not prescribed in the plan as are determined on a site-by-site basis, it is not a case of one size fits all. Further, including a figure in policy would not pass the independent examination of the Plan. See Government guidance on minerals for further details (https://www.gov.uk/guidance/minerals Para 018).

What alternatives have we considered?

Include general policies in the Plan for managing the impacts of all forms of development, including minerals development, with separate policies to address matters specific to minerals development.

Rely on higher-level national planning policy to manage the impacts of mineral development and the restoration/after-use of mineral workings.

Which existing policies will be replaced by this policy?

MDC1 - Impacts of mineral development

MDC2 - Pollution, health, quality of life and amenity

MDC3 - Sites with National Designations

MCS5 - Extensions to Aggregates Sites

MCS6 - Building and Roofing Stone

MCS7 - Residential and Sensitive Land Uses

MCS8 - Rutland Water

MDC6 - Biodiversity and Geological Conservation Interests

MDC7 - Water Resources

MDC8 - Flooding

Sites for Minerals Development

What will the policy do?

The existing commitments for crushed rock provide crushed rock surplus to requirements over the plan period and therefore no sites have been identified. Further, no sites for the supply of limestone and clay, required to support Ketton Cement Works, have been identified - the identification of the cement AoS and Policy MIN4 enables sites to come forward which are in line with relevant Local Plan policies.

To support a continued supply of building stone, a site for building stone extraction at New Road, Hooby Lane is identified in Policy MIN5, with its location shown in Figure 7.

(5) Policy MIN5 - Site-specific allocations for the extraction of building stone

Proposals for the extraction of building stone at the following site will be permitted in accordance with other relevant Local Plan policies:

- M1 New Road, Hooby Lane (yield unknown)

Why is this policy needed?

Crushed rock (limestone)

The NPPF requires a steady and adequate supply of minerals. Regarding crushed rock (limestone), the total provision to be met for crushed rock during the plan period (from 1 January 2021 to 31 December 2041) is 5.66Mt. Permitted reserves as of 1 February 2023 total 16.2Mt, of which most remains[4]. Thistleton Quarry makes up 6.4Mt of the permitted reserves and is currently inactive, however the site is considered by industry and part landowner British Steel Pension Fund (BSPF), to be undeliverable on the basis the site is not economically viable due to the costs involved of developing the associated haul road and annual limit on sales. BSPF are willing to exchange Thistleton Quarry for an alternative, deliverable and viable site, at New Road, Hooby Lane (also in their ownership) which would primarily be for building stone extraction[5]. The surrender of the Thistleton permission will remove the uncertainty surrounding the Thistleton resource in the plan and is supported in principle subject to the planning application process and compliance with relevant Local Plan policies. The Local Plan has therefore gone down this route and allocated the New Road site and not taken the Thistleton quarry site as a commitment in its provision figures for crushed rock, although it accepts that formal extinguishment of the Thistleton permission would not be possible until New Road is granted permission. Extraction at New Road would support the supply of building stone in Rutland.

The existing commitments, excluding the 6.4 Mt reserve at Thistleton, will still provide crushed rock surplus to requirements over the plan period; and as such there is no need to allocate any sites for the extraction of crushed rock.

Due to the limited number of current crushed rock permissions, the total aggregate output may be affected if a site ceases operations or significantly reduces production. For these reasons, the situation at all sites will be monitored to ensure that a sufficient supply of minerals is maintained. The possible need for additional sites is accounted for through Policy MIN4 Development criteria for mineral extraction, which allows unallocated sites to come forward where in line with relevant Local Plan policies and where it can be demonstrated that site is required to secure provision or maintain landbanks and cannot reasonably, or would not otherwise be met from, committed or allocated reserves.

Limestone and clay

To support a continued supply of building stone, a site for building stone extraction is allocated. Located within the LABS AoS, it is in line with the mineral's spatial strategy. Limestone for building stone purposes is currently produced from three quarries: Clipsham, Woolfox and Hooby Lane. Clipsham and Woolfox quarries also produce limestone for use as agricultural lime in addition to crushed rock. Overall, output of limestone for these end uses (i.e., building stone) is limited and therefore the Plan does not identify a specific provision rate.

A sufficient supply of limestone and clay is required to support Ketton Cement Works and meet its annual cement production rate of approximately 1.4Mt. Permitted limestone and clay reserves used in the manufacture of the cement at Ketton are sufficient to last until around the middle of the plan period[6]. The need for additional reserves is accounted for with the identification of the cement AoS, as it is understood to contain appropriate reserves to maintain a landbank of at least 15 years over the plan period. In the event that a supply cannot be reasonably met from within the cement AoS or committed reserves; Policy MIN4 Development Criteria for Mineral Extraction enables sites to come forward where in line with relevant Local Plan policies.

A specific provision figure for brickclay is not identified. The existing permission for brickclay extraction at Little Casterton expires around the beginning of the plan period and hence additional reserves may be required. Any new proposals for brickclay extraction will need to demonstrate they are in compliance with relevant Local Plan policies.

What you told us about the topic

The Issues and Options consultation asked about the supply and demand for minerals under Issue 11. Respondents suggested the Plan should support the supply of building stone and cement production at Ketton and be sufficiently flexible to enable any unforeseen demand for minerals to be met.

As a result of the consultation responses, Policy MIN4 supports the provision of building stone, and limestone and clay to support cement production at Ketton. There is sufficient flexibility built into the plan to enable demand to be met from existing sites and new sites (including allocated and unallocated sites). Any proposal for extraction will be required to take into account the current reserve and supply position, provision rate (where relevant) and landbanks, which are monitored and reported on annually in the LAA.

What alternatives have we considered?

Identify specific sites for crushed rock extraction and recycled aggregate production.

Not including a specific site/s for building stone in the plan and instead relying on general mineral plan policies to develop sites.

Safeguarding minerals development

What will the policy do?

Existing sites and facilities for the storage, handling and processing of minerals and materials for concrete production as well as associated facilities for the transport of such materials form part of the infrastructure network that supports minerals development. Some sites can be of a relatively low value land use and may be vulnerable to redevelopment for other uses and so should be safeguarded from proposals for non-minerals development where appropriate.

(4) Policy MIN6 - Safeguarding of minerals development

To safeguard the provision to be delivered by the allocated and committed mineral extraction sites, proposals for non-minerals development:

- within an allocated site must demonstrate that the site is no longer required to support the delivery of the adopted provision rate and/or to maintain landbanks (with reference to the most recent Local Aggregate Assessment); or

- adjacent to an allocated or permitted site must demonstrate that the proposed development would not prevent or unreasonably restrict the future extraction of minerals from the allocated site.

In order to ensure that there is a sufficient supply of material to support current community and businesses and planned growth the following minerals development will be safeguarded unless proposals for non-minerals development can demonstrate that alternative provision in the vicinity can be made, or there is no longer a need for the facility at that location.

Minerals development to be safeguarded includes:

- existing, planned and potential rail heads, rail links to quarries, wharfage and associated storage, handling and processing facilities for the bulk transport by rail or inland waterways of minerals, including recycled, secondary and marine-dredged materials; and

- existing, planned and potential sites for concrete batching, the manufacture of coated materials, other concrete products and the handling, processing and distribution of substitute, recycled and secondary aggregate material.

Why is this policy needed?

National policy requires MPAs to safeguard existing, planned and potential facilities and sites for the storage, handling and transport of minerals to ensure that sites for these purposes are available should they be needed; and prevent sensitive or inappropriate development that would conflict with the use of sites identified for these purposes. MPAs are also required to safeguard allocated and committed mineral extraction sites from non-minerals development, to facilitate the steady and adequate supply of minerals.

What you told us about the topic

The Issues and Options consultation asked about safeguarding mineral resources and infrastructure under Issue 11. Respondents recommended the cement processing plant at Ketton is safeguarded to enable continuation of cement production.

As a result of the consultation responses, Policy MIN6 safeguards those sites with planning permission for minerals related development/supporting infrastructure, which includes Ketton Cement Works.

What alternatives have we considered?

Rely on higher-level national planning policy to safeguard minerals development and infrastructure.

Which existing policies will be replaced by this policy

MCS10 - Minerals Safeguarding

MDC10 - Development in Mineral Safeguarding Areas

Borrow pits

What will the policy do?

Large quantities of aggregates or clay may be needed in association with major construction and engineering works, where the mineral resource exists within the local area it may be preferable to supply this need from a borrow pit rather than import the materials from further afield. The timeframe for extraction from the borrow pit should not exceed that of the associated construction or engineering works.

(2) Policy MIN7 - Borrow pits

Permission will be granted for borrow pits where it can be demonstrated that:

- extraction of mineral from the borrow pit constitutes the most appropriate supply option with reference to the type and quality of the mineral and proximity to other mineral extraction sites;

- the estimated size of the resource, and proposed extractive operations, is commensurate to the estimated needs of the associated construction or engineering works;

- the borrow pit is within close proximity to the associated works that it is intended to supply and minimises the use of public highways in transporting the mineral;

- the proposal avoids and/or mitigates potentially adverse impacts to acceptable levels and is environmentally feasible;

- the site will be progressively restored to an acceptable condition and after use and completed as soon as possible following cessation of the associated works; and

- inert waste arising from the associated works should be used in restoration of the borrow pit where appropriate. The site will be progressively restoration to an acceptable condition and after use and completed as soon as possible following cessation of the associated works.

Why is this policy needed?

The NPPF requires a steady and adequate supply of minerals to provide the infrastructure, buildings, energy and goods that the country needs. Borrow pits promote sustainable development by helping conserve mineral resources that might otherwise be lost. Minerals extracted from borrow pits contribute to the County's aggregate requirements and may help to avoid the use of higher-quality reserves elsewhere.

What you told us about the topic

In the Issues and Options consultation no specific points were raised about borrow pits.

What alternatives have we considered?

A policy allowing borrow pits which are tied to a named scheme and scheme duration

Not including a specific borrow pit policy in the plan and instead relying on general plan policies

The preferred approach is to have a criteria-based policy to ensure borrow pits are developed in the most sustainable and appropriate locations and manage the impacts of mineral development on the wider environment.

Other forms of minerals development

What will the policy do?

The policy reinforces that proposals for other forms of minerals development[7] will be required to be in compliance with relevant Local Plan policies and demonstrate that they are environmentally feasible with any potentially adverse impacts able to be avoided and/or mitigated to acceptable levels.

(3) Policy MIN8 - Development criteria for other forms of minerals development

Permission will be granted for other forms of minerals development where it can be demonstrated that the development complies with relevant Local Plan policies and avoids and/or mitigates potentially adverse impacts to acceptable levels.

Why is this policy needed?

National policy requires proposals for minerals development to be environmentally acceptable and avoid and/or minimise potentially adverse impacts to acceptable levels.

What you told us about the topic

In Issue 11 of the Issues and Options consultation we asked about how best to manage the impact of mineral development. 54% of those responding to this question agreed that the Plan should include specific policies for managing the impacts of mineral development on the wider environment.

As a result of the consultation responses, Policy MIN8 is tailored specific to minerals development to ensure sites for mineral development are developed in the most sustainable and appropriate locations and manage the impacts of mineral development, including the requirement for appropriate mitigation measures to be identified to avoid and/or minimise impacts to an acceptable level.

What alternatives have we considered?

Include general policies in the Plan for managing the impacts of all forms of development, including minerals development.

Rely on higher-level national planning policy to manage the impacts of mineral development.

Waste

Capacity Requirements and Spatial Strategy for Waste Development

What will the policy do?

Rutland is the Waste Planning Authority (WPA) for the administrative area of Rutland. In line with national policy, the policy identifies the level of need for the management of waste streams throughout the plan period and plans for the provision of new capacity by identifying sufficient opportunities to meet the identified needs of Rutland. The Local Plan also sets out development criteria against which planning applications will be assessed.

(4) Policy WST1 - Capacity requirements and spatial strategy for waste development

Waste management capacity requirements

The development of a sustainable waste management network for Rutland will be supported through the recognition of waste as a resource and will involve the provision of facilities to meet the indicative waste management capacities. Waste development within the County will focus on the provision of preliminary and supporting facilities. Rutland is not considered an appropriate location for large-scale advanced treatment facilities unless the facility would form an ancillary activity to industrial operations where the waste would be utilised as an alternative fuel source.

The indicative waste management capacity requirements up to 2041 include:

- preparing for reuse and recycling capacity of 27,000 tonnes per annum (tpa), plus an additional 1,000tpa for civic amenity facilities,

- biological processing capacity of 9,000tpa,

- inert recycling and/or soil treatment of <1,000tpa,

- advanced treatment of 26,000tpa and

- inert recovery 43,000tpa.

Waste management spatial strategy

Within Rutland facilities to meet the indicative waste management capacity requirements should be focussed at Oakham, Uppingham and the Larger Villages. Within these areas waste development should be located within industrial areas or integrated with new residential and commercial development and be of an appropriate scale. Co-location of facilities for advanced treatment with industrial operations where the output(s) are able to be utilised as an alternative fuel or for energy generation is supported.

In other areas, including the countryside, the development of preliminary treatment facilities should be linked to the management of agricultural wastes, or where a rural location is more appropriate due to the nature of operations or the relationship with rural activities. Within these areas, preference would be for the use of redundant agricultural and forestry buildings and their curtilages.

Industrial sites and brownfield land including existing minerals and waste sites, disused railheads and wharves are appropriate, in principle, to accommodate inert recycling facilities. At locations that are only temporarily in use, only temporary facilities will be permitted.

Development on the edge of Stamford, large redevelopments and other similar proposals would be considered where consistent with their role and relevant Local Plan policies.

The current role of the Ketton cement works, being a nationally significant facility for the use of alternative fuels, is to be maintained.

The deposit of inert waste to land should be directed towards permitted mineral extraction sites to facilitate restoration (as inert recovery); however inert fill could be permitted for agricultural improvement or other purposes as long as it could be demonstrated that it would not prejudice restoration of any mineral extraction sites (existing and allocated).

Waste disposal capacity requirements and strategy

Rutland is not considered an appropriate location for non-hazardous disposal facilities. Although disposal forms the least desirable solution, it is important to note that there will still be a requirement for disposal. The estimated non-hazardous disposal capacity requirement up to 2041 includes 1,000tpa for non-hazardous waste, as well as an additional 12,000tpa of residual waste materials.

Hazardous waste

Rutland is not considered an appropriate location for hazardous waste management and disposal facilities. The estimated requirement for hazardous waste management up to 2041 includes: recovery and treatment capacity of approximately 1,000tpa.

Radioactive waste management and disposal

Rutland is not considered an appropriate location for radioactive waste management or disposal facilities. Proposals for facilities for the management or disposal of radioactive waste should demonstrate how the proposal forms the most appropriate management option and enables waste to be managed or disposed of in the nearest appropriate installation, in addition to addressing the development criteria set out in Policy WST2

Why is this policy needed?

The NPPF does not specifically address waste matters. Detailed waste planning policies are set out in the National Planning Policy for Waste (NPPW). The NPPW is to be read in conjunction with the NPPF, the Waste Management Plan for England and National Policy Statements (NPS) for wastewater and hazardous waste.

All forms of development and activities produce waste. It is important in creating sustainable communities that waste management is incorporated into new development and that there is a social change towards recognising waste as a resource and where communities and businesses take more responsibility for the waste they produce.

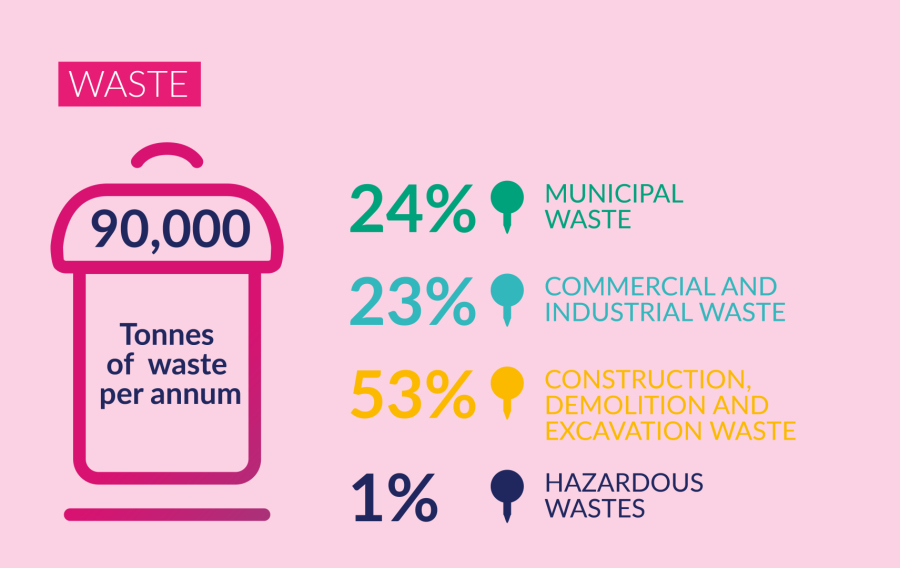

It is estimated that Rutland produces just under 90,000 tonnes per annum (tpa) of various types of waste, including municipal (24%), commercial and industrial (23%), construction, demolition and excavation (53%) and hazardous (1%) as set out in Appendix 10. Rutland does not produce low-level radioactive waste (LLW) from the nuclear industry however a very small amount of LLW from the non-nuclear industry is produced from the Leicestershire and Rutland County areas.

The majority of Rutland's waste is exported to surrounding counties where it is recycled, composted, treated, or disposed of to landfill. Since 2014 a significant proportion (around 40%) of municipal waste, previously disposed of to landfill, has been diverted to an advanced treatment facility in Nottingham for recovery; this continues to occur. Limited advanced treatment of other waste streams has been reported.

The amount of waste generated in Rutland is likely to increase over the plan period, estimated at 118,000 tonnes (t) by 2041, resulting in a capacity gap between current operational capacity and future requirements.

An assessment of the potential future requirements for facilities has demonstrated that there are opportunities in Rutland for increasing the current waste management capacity, particularly in relation to preparing for reuse and recycling, anaerobic digestion and composting.

There is a potential requirement for the following preliminary treatment facilities:

- one to two small-scale materials recycling facilities, plus either additional capacity at the existing civic amenity sites or additional site(s) as required, and

- one small scale composting or anaerobic digestion facility.

Given the number and scale of facilities, it is estimated that around three hectares of land is needed to accommodate this requirement.

The two existing civic amenity sites in Cottesmore and North Luffenham will be retained. Additional capacity for civic amenity sites will be provided either through an extension to existing sites or where required new site(s) associated with areas of significant development.

The operational capacity for large preliminary and advanced treatment facilities cannot be sustained from waste arisings from within Rutland alone. Over the mid to long-term of the plan period the development of a small-scale advanced treatment facility may become viable. Such development is likely to be more viable within Rutland where the treatment capacity forms an ancillary activity to industrial operations. As such co-location of facilities for advanced treatment with industrial operations where the output(s) are able to be utilised as an alternative fuel or for energy generation is supported. There may be the potential for treatment capacity to be increased through the use of alternative fuels at the nationally significant Ketton Cement Works[8].

Until such a facility is provided, it is likely that the exporting of waste to surrounding counties for treatment will continue and that amounts will increase in line with meeting waste management targets.

Regional self-sufficiency will be promoted through sustainable patterns of waste movements in relation to urban areas in neighbouring counties. In line with government policy, the need for additional waste management capacity of more than local significance has been taken into account. This involved strategic waste movements being identified and the Council engaging with WPAs accommodating facilities that receive such wastes (originating from Rutland) in line with the Duty to Co-operate. As a result, no strategic matters were identified regarding continuation of such waste movements. The County recognises the importance of cross-boundary movements and will continue to co-operate with relevant WPAs to address strategic matters and facilitate the continuation of such arrangements.

Waste related development will be predominantly focused in Oakham, Uppingham, and the Larger Villages in line with the spatial strategy. This will maximise the use of existing infrastructure networks and facilitate communities and businesses taking greater responsibility for their waste. Waste developments should be co-located together and with complementary activities, for example within industrial areas or integrated with new residential and commercial development.

Development on the edge of Stamford, large redevelopments, or other similar proposals would be considered where consistent with the role of the locale in accordance with spatial strategy and hierarchy. Facilities in these areas should deal with the waste generated from identified urban areas or the redevelopment and on-going use of such establishments. The co-location of waste management facilities together and with complementary activities is supported.

In other areas, including the countryside, redundant agricultural and forestry buildings and their curtilages may also provide suitable opportunities for preliminary treatment - in particular for the management of agricultural wastes or where a rural location is more appropriate due to the nature of operations or the relationship with rural activities, for example composting and anaerobic digestion.

Facilities for inert recycling should be directed towards industrial sites and where associated with the re-use of previously development land such as existing waste sites, as an ancillary activity on existing mineral extraction sites or disused railheads and wharves. Where a site is subject to redevelopment, there may be an opportunity to accommodate temporary plant: however, the operational life would be limited to that of the redevelopment.

The deposit of inert waste to land should be directed towards permitted mineral extraction sites in order to facilitate restoration. The deposit of inert waste to land for the purpose of engineering works, agricultural improvement or land reclamation should demonstrate that the proposal would not divert significant amounts of inert waste material from mineral sites and would not prejudice restoration of mineral extraction sites. The deposition of inert waste to land may also constitute recovery in some cases (where in compliance with Environmental Permitting Regulations), in particular where associated with the restoration of permitted mineral extraction sites.

There are currently no operational non-hazardous landfill[9] sites within Rutland. The County is not considered appropriate as an area to accommodate a new landfill site. The exporting of waste to surrounding counties for disposal to landfill will continue but the amount of waste requiring disposal is anticipated to reduce as the capacity of other forms of waste management increases.

There are currently no facilities for the management or disposal of hazardous and radioactive wastes within Rutland. The County does not produce substantial quantities of these waste materials and is not considered an appropriate location for such facilities.

The location of waste related development should be in accordance with the spatial strategy (Policy WST1) and with allocations (identified in Policy WST3) and set out in Figure 8.

Figure 8 - Proposed allocations for minerals extraction and waste management

What you told us about the topic

In Issue 11 of the Issues and Options consultation we asked you to consider the most appropriate option for identifying sites for waste management. Most respondents (59%) wanted the plan to include criteria-based policies to ensure that sustainable waste management facilities are developed in the most sustainable and appropriate locations. You told us that the Plan should encourage, and facilitate, net self-sufficiency in waste management and not rely on surrounding authorities to deal with the counties waste, and that waste is managed as close to the source as possible. You welcomed the approach to carry out an evidence base study to understand waste needs, and recommend the plan includes waste targets and recognises the benefits of the co-location of mineral extraction sites and aggregate recycling facilities.

As a result of the consultation responses, Policy WST1 will focus on provision of preliminary and supporting facilities whilst recognising waste as a resource. Highlighting the indicative waste management capacity requirements up to 2041 and sets a spatial strategy that directs facilities to Oakham, Uppingham and Larger Villages. Deposit of inert waste is to be directed to mineral extraction sites to facilitate restoration.Co-location of facilities for advanced treatment with industrial operations where the output(s) are able to be utilised as an alternative fuel or for energy generation is supported.

What alternatives have we considered?

Identify specific sites or locations in the Local Plan for sustainable waste management facilities.

Use criteria-based policies to ensure that sustainable waste management facilities are developed in the most sustainable and appropriate locations

Do not include any specific sites/locations or criteria-based policies and rely on national policy

Which existing policies will be replaced by this policy?

CS25 - Waste management and disposal

MCS11 - Recycled and Secondary Aggregates

Waste-related development

What will the policy do?

The Policy gives development criteria to provide clear guidance on how applications for waste-related development will be decided including planning considerations and requirements. In this manner the development criteria provide clarity for both the community and industry. The development criteria for waste-related development are applicable to both allocated and unallocated sites.

(3) Policy WST2 - Waste-related development

Waste-related development will be acceptable in principle where it:

- is located on an allocated site;

- supports the spatial strategy for waste management and disposal, facilitates the delivery of Rutland's capacity requirements and, in doing so, identifies the type(s) and origin of waste intended to be received on-site as well as the destination of outputs;

- enables communities and businesses to take more responsibility for their own waste and supports the management and disposal of waste in line with the proximity principle;

- supports the move towards a circular economy where possible and is compatible with the waste hierarchy, including the re-use of energy, heat and residues where appropriate;

- will not result in unacceptable adverse impacts in relation to water quality and resources, flood risk, land instability, landscape and visual impacts, nature conservation, historic environment, traffic and access, air emissions (including dust), odours, bio aerosols, vermin and birds, noise, light, vibration, litter, potential land use conflict, amenity and cumulative impact(s);

- ensures restoration of sites (in particular temporary facilities) as soon as possible after cessation of operations to an acceptable condition and to a stable landform; and

- specific to proposals for extensions to existing sewage treatment works (STWs) or new STWs, the increased capacity is required to support sustainable development, operations do not have unacceptable impacts and the scale of development reflects the role of the location with respect to the settlement hierarchy.

Proposals for waste-related development must identify and determine the nature and extent of potentially adverse impacts likely to result from the development. Where potentially adverse impacts are likely to occur appropriate mitigation measures are to be identified in order to avoid and/or minimise impacts to an acceptable level. Where applicable a site-specific management plan should be developed to ensure the implementation and maintenance of such measures throughout construction, operation, decommissioning and restoration works.

Why is this policy needed?

The overall approach, including the spatial strategy, for waste management and disposal is set out through Policy WST1 (Capacity requirements and spatial strategy for waste development). A specific site for waste management is allocated in this Plan, whilst unallocated sites for waste management and disposal are able to come forward where in line with the spatial strategy and development criteria. Although a site may be allocated for waste development, it will still require a planning application to be submitted and assessed against the development plan and other relevant policies.

Waste-related development has the potential to have an adverse impact on the receiving environment. Although some impacts may be similar to those resulting from other forms of development, such as industrial land use, others are specific to waste-related development (and vary dependant on the type of facility). It is important that potentially adverse impacts are identified, and appropriate measures put in place in order to avoid and/or minimise such impacts to an acceptable level, for example air filtration systems, separation areas, bunding, acoustic screening and strategic site layout (including site access and roads)[10].